STUDY AND WRITING SKILLS

95

9.5

1

9

WRITING SKILLS

DESCRIBING A PROCESS

7

Read the description of how aircraft are made and

answer the questions.

1

Why are the following used to produce an aircraft?

a

a model

b

wind tunnels

c

flight tests

2

What document must a construction company get

before it can sell its aircraft?

8

Using the passive

In English, we prefer to start a

sentence with information that is already known, not

new. We sometimes use the passive to put known

information at the beginning of a sentence. For example:

Aircraft production

is a huge and costly business.

Most aircraft

are made …

We are unlikely to write:

Aircraft production

is a huge and costly business.

Companies make

most aircraft

…

Find two more examples of this in the text.

9

There are several stages in the production and launch

of a new motorbike. Look at the notes below and put

them in the correct order. Think about how the passive is

sometimes used at the beginning of a sentence. The first

and last have been numbered.

F

Show the new motorbike at trade exhibitions all

over the world.

F

Plan the new motorbike and produce the first

designs. (Design team)

F

Contact journalists and invite them to test drive the

new motorbike.

F

Changes are made to the prototype and the design

is modified. (R&D department)

F

Build the first prototype, with the help of engineers.

(R&D department)

F

The prototype is tested on special roads. Check if there

are any problems and if any changes are necessary.

F

Do further tests, then make more modifications and

changes to the engine.

F

Results of the test drive are recorded and the

journalists prepare articles about the new bike.

F

Mass-produce the new motorbike. Launch an

international marketing campaign.

10

Write an article on the stages in the production and

launch of a new motorbike, for inclusion in some school

course materials on engineering processes. Use the notes

above and the linkers in the box to structure your article.

first of all next after that then finally

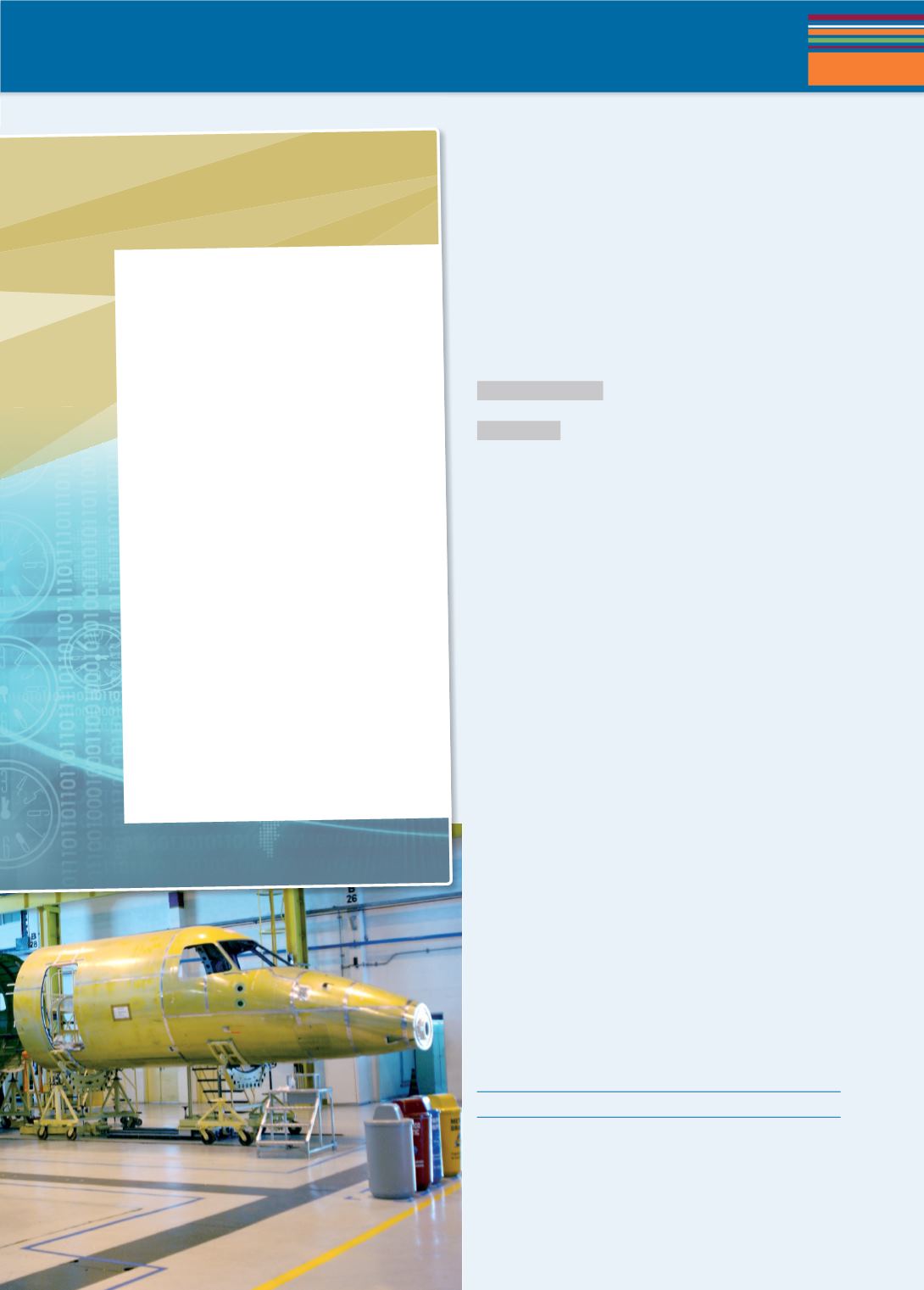

How aircraft are made

Aircraft production is a huge and costly

business. Most aircraft are made by companies

who can produce them in large quantities and

who can invest time in planning as well as

production. Planning alone can take up to 12

years for a large aircraft and production can

also be a very long process. The production

stages are as follows.

First, the construction company produces

designs for the aircraft. These designs are

used for the initial simulations. Then a

model of the aircraft is put in a wind tunnel.

The way the air moves around the model

is studied by engineers and scientists, as

well as how the model acts in the tunnel.

This gives them a good idea of how a real,

life-sized aircraft of the same design will fly.

Smaller parts of the aircraft are also tested in

wind tunnels.

Next a prototype of the aircraft is made,

and after that a limited number of aircraft

are produced to test on the ground.

Representatives from a government aviation

agency often make the first flight. Flight

tests continue until all the requirements

are met. Finally, the government agency

authorises the construction company

to begin production of the aircraft. A

certificate is issued and the aircraft is sold

all over the world.